|

Ningbo Joy Industrial & Trading Co.,Ltd.

|

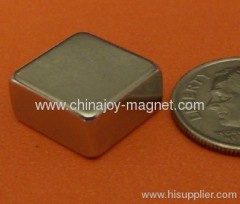

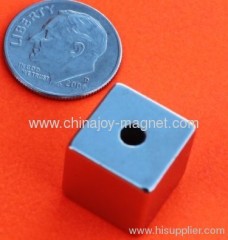

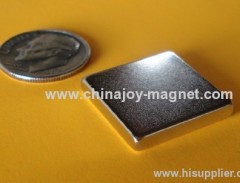

Rare Earth Magnets 1/2 in x 1/2 in X 1/4 in Neodymium Block N42

| Price: | 0.8~1.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Neodymium magnet , a type of rare earth magnet, is a permanent magnet made from neodymium, iron, boron and other minor elements.

Product Description:

Rare earth magnets Neodymium ndfeb are the world's strongest magnets. All magnets are not created equal! Applied Magnets offers the highest quality magnets with consistent performance at lowest price. Our strong magnets are designed & manufactured to meet stringent quality standards using the latest technology.

Neodymium magnet (also known as Neo, NdFeB, NIB or super magnet) , a type of rare earth magnet, is a permanent magnet made from neodymium, iron, boron and other minor elements.

Strong Magnet Grade N42 , stronger than N40, N38 and N35

BrMax: 13200 gauss

Neodymium magnet (also known as Neo, NdFeB, NIB or super magnet) , a type of rare earth magnet, is a permanent magnet made from neodymium, iron, boron and other minor elements.

Strong Magnet Grade N42 , stronger than N40, N38 and N35

BrMax: 13200 gauss

Rare earth magnets N42 Grade 0.5" x 0.5" x 0.25" Thick Neodymium Iron Boron NdFeB Block Magnet

Nickel-Copper-Nickel triple layer coated for maximum durability and protection again corrosion

ISO Certified, top notch quality and superior performance guaranteed

Magnetized through the Thickness

ISO Certified, top notch quality and superior performance guaranteed

Magnetized through the Thickness

Contact us for rare earth magnets wholesale discount

Approximate pulling force: 13.5 lbs

Neodymium Iron Boron (NdFeB) magnets, the most powerful permanent magnets available today, possess high energy up to 52MGOe and wonderful coercive force.

1. Primary Material: Neodymium, iron, boron, rare-earth material

2. Maximum working temperature: 80-220 degree celcius

3. Density: 7.5 to 7.6g/CMM³

4. Application: Motors, Windmill, Acoustics, Magnetic separators, Auto, VCM, MRI, Mobile accessories

5. Grade available:

N35-N52, N33M-N50M, N30H-N48H, N30SH-N45SH, N28UH-N40UH, N328EH-N35EH, N30AH-N33AH

Strong Disc Neodymium Iron Boron Magnet

- High remanence, high coercive force, high energy, etc

- High resistance to magnetic demagnetization

- Excellent cost to performance ratio

- Not suitable for application which exposed to high temperatures.

- Widely used in mini-motors, wind generators, meters, sensors, speakers, magnetic suspension system, magnetic transmission machine and other industrial applications.

- Very easy to corrosion in humid environments, so it is necessory to do the surface treatment according customers' requirements. We can offer the coatings, such as Zinc, Nickel, Nickel-copper-nickel, Silver, gold-plating, Epoxy coating, etc

Magnetic properties of main grades

| Grade | Residual Induction | Coercive Force | Intrinsic Coercivity | Maximum Energy Product | TW | ||||

| Br | BHC | IHC | (BH)max. | ||||||

| kGs | T | kOe | kA/m | kOe | kA/m | MGOe | kJ/m3 | ℃ | |

| N33 | 11.3-11.7 | 1.13-1.17 | ≥10.5 | ≥836 | ≥12 | ≥955 | 31-33 | 247-263 | 80 |

| N35 | 11.7-12.1 | 1.17-1.21 | ≥10.9 | ≥868 | ≥12 | ≥955 | 33-36 | 263-287 | 80 |

| N38 | 12.1-12.5 | 1.21-1.25 | ≥11.3 | ≥899 | ≥12 | ≥955 | 36-39 | 287-310 | 80 |

| N40 | 12.5-12.8 | 1.25-1.28 | ≥11.6 | ≥923 | ≥12 | ≥955 | 38-41 | 302-326 | 80 |

| N42 | 12.8-13.2 | 1.28-1.32 | ≥11.6 | ≥923 | ≥12 | ≥955 | 40-43 | 318-342 | 80 |

| N45 | 13.2-13.8 | 1.32-1.38 | ≥11.0 | ≥876 | ≥12 | ≥955 | 43-46 | 342-366 | 80 |

| N48 | 13.8-14.2 | 1.38-1.42 | ≥10.5 | ≥835 | ≥11 | ≥876 | 46-49 | 366-390 | 80 |

| 33H | 11.3-11.7 | 1.13-1.17 | ≥10.5 | ≥836 | ≥17 | ≥1353 | 31-34 | 247-271 | 120 |

| 35H | 11.7-12.1 | 1.17-1.21 | ≥10.9 | ≥868 | ≥17 | ≥1353 | 33-36 | 263-287 | 120 |

| 38H | 12.1-12.5 | 1.21-1.25 | ≥11.3 | ≥899 | ≥17 | ≥1353 | 36-39 | 287-310 | 120 |

| 40H | 12.4-12.8 | 1.24-1.28 | ≥11.6 | ≥923 | ≥17 | ≥1353 | 38-41 | 302-326 | 120 |

| 42H | 12.8-13.2 | 1.28-1.32 | ≥12.0 | ≥955 | ≥17 | ≥1353 | 40-43 | 318-342 | 120 |

| 33SH | 11.3-11.7 | 1.13-1.17 | ≥10.6 | ≥844 | ≥20 | ≥1592 | 31-34 | 247-272 | 150 |

| 35SH | 11.7-12.1 | 1.17-1.21 | ≥11.0 | ≥876 | ≥20 | ≥1592 | 33-36 | 263-287 | 150 |

| 38SH | 12.1-12.5 | 1.21-1.25 | ≥11.4 | ≥907 | ≥20 | ≥1592 | 36-39 | 287-310 | 150 |

| 40SH | 12.4-12.8 | 1.24-1.28 | ≥11.8 | ≥939 | ≥20 | ≥1592 | 38-41 | 302-326 | 150 |

| 28UH | 10.2-10.8 | 1.02-1.08 | ≥9.6 | ≥764 | ≥25 | ≥1990 | 26-29 | 207-231 | 180 |

| 30UH | 10.8-11.3 | 1.08-1.13 | ≥10.2 | ≥812 | ≥25 | ≥1990 | 28-31 | 223-247 | 180 |

| 33UH | 11.3-11.7 | 1.13-1.17 | ≥10.7 | ≥852 | ≥25 | ≥1990 | 31-34 | 247-271 | 180 |

| 28EH | 10.4-10.9 | 1.04-1.09 | ≥9.8 | ≥780 | ≥30 | ≥2388 | 26-29 | 207-231 | 200 |

| 30EH | 10.8-11.3 | 1.08-1.13 | ≥10.2 | ≥812 | ≥30 | ≥2388 | 28-31 | 223-247 | 200 |

Note:

aB - reversible temperature coefficient of induction.

aB - reversible temperature coefficient of induction.

Shapes and sizes available (as standard):

Shapes: Blocks/plates, disks/rods, rings, segments

Two (four) poles

Note: More complicated shapes and any magnetic configuration can be provided by special order.

Shapes: Blocks/plates, disks/rods, rings, segments

Two (four) poles

Note: More complicated shapes and any magnetic configuration can be provided by special order.

Standard sizes:

Blocks/plates

| Min, mm | Max, mm | |

| W | 2 | 70 |

| T | 1.5 | 50 |

| L | 1 | 15 |

Disks/rods with axial magnetic texture

| Min, mm | Max, mm | |

| Dia | 5 | 70 |

| h | 1.2 | 12 |

Disks/rods with diametrical magnetic texture

| Min, mm | Max, mm | |

| Dia | 2 | 12 |

| h | 1.2 | 40 |

Segments with axial magnetic texture

| Min, mm | Max, mm | |

| OD | 96 | 96 |

| ID | 48 | 55 |

| h | 5 | 12 |

| Opening angle, degree | 35 | 45 |

Segments with diametrical magnetic texture

| Min, mm | Max, mm | |

| OD | 50 | 120 |

| ID | 32 | 180 |

| h | 8 | 50 |

| Opening angle, degree | 30 | 60 |

Rings with axial magnetic texture

| Min, mm | Max, mm | |

| OD | 5 | 70 |

| ID | 3 | 26 |

| h | 1.2 | 40 |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

2 In 1 Socket

2 In 1 Flashlight

2 In 1 Vacuum Cleaner

2 In 1 Pen

2 In 1 Card Reader

2 In 1 Usb Reader

More>>