|

Ningbo Joy Industrial & Trading Co.,Ltd.

|

Customized Magnetic Shields Special Offer

| Price: | 0.1~10.0 USD |

| Payment Terms: | T/T,L/C, |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

To avoid effect of this field on sensitive equipments, magnetic shielding is required. e.g. cathode ray tubes, photomultiplier tubes, etc.

product name: Magnetic Shields

We are surrounded by magnetic fields (both AC and DC) from the earth's magnetic field to man-made sources such as magnets, motors and transformers. To avoid effect of this field on sensitive equipments, magnetic shielding is required. e.g. cathode ray tubes, photomultiplier tubes, audio transformers, scanning electron microscopes, position sensors.

We are surrounded by magnetic fields (both AC and DC) from the earth's magnetic field to man-made sources such as magnets, motors and transformers. To avoid effect of this field on sensitive equipments, magnetic shielding is required. e.g. cathode ray tubes, photomultiplier tubes, audio transformers, scanning electron microscopes, position sensors.

The shield is made of soft ferromagnetic material with a high Permeability (μ). 36%, 48% &80% NiFe are most commonly used soft magnetic alloys. In order to have a low Hysteresis, the shield is annealed after shaping. Any stress after annealing will deteriorate the performance and hence should be avoided.

How does a magnetic shield work?

There is no known material that can block magnetic fields without itself being attracted to the magnetic force. A magnetic shield acts as a kind of sponge redirecting the magnetic field around the shield instead of passing through the sensitive instrument which is being shielded. A good magnetic shielding material must have high permeability which means that the magnetic field lines are strongly attracted to the shielding material. If the magnetic field is too high for the material chosen it will saturate and become ineffective. In this case, a multi layer shield with a combination of the above alloys can be used.

Shielding Factor:

The Shielding Factor is defined as the ratio between the external and the internal field when the shield is placed in an area with a homogenous magnetic field.

The Shielding Factor is defined as the ratio between the external and the internal field when the shield is Shielding Factor = External Field / Internal Field.

Saturation:

The magnetic saturation of the shield is given by the magnetic properties of the shield material.

Ferromagnetic material saturates between 0.5 and 2 Tesla. Once the shield is saturated, its apparent Permeability will decline to the value 1, meaning that the shield acts like air. A saturated shield does not guide nor attract magnetic flux lines. Therefore, the shield design has to be chosen such that the field generated by the current and the field generated by external sources do not saturate the shield material.

General Principles of shield Designing:

In the following sections we will describe how the different geometries influence the Shielding Factor, Magnetic gain and Saturation level.

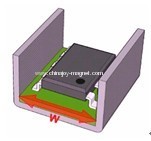

Influence of Width W:

View | Influence |

| W has an influence on the magnetic gain and also on the Shielding Factor. We recommend choosing W as small as possible. The magnetic gain and the Shielding Factor are reciprocally proportional to W. |

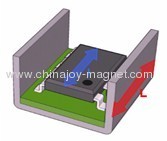

Influence of Length L:

View | Influence |

| L has an influence on the Shielding Factor. We recommend choosing L as big as possible. The absolute minimum of L is the length of the part (visible in blue). The maximum is open, but 8mm more than L is sufficient. The Shielding Factor increases with the length of the shield L. Once the shield is long enough, approximately the length of the part ( l +8mm), a longer shield will not improve the Shielding Factor significantly. |

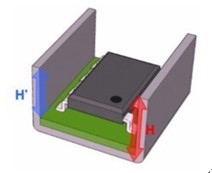

Influence of Height H:

View | Influence |

| H has an influence on the magnetic gain and on the Shielding Factor. We recommend making H' (from the top of the PCB surface to the end of the shield) about 10mm. The absolute minimum of H' is about 6mm (visible in blue). The maximum is not relevant, but the shielding effect will not increase significantly for a shield with H longer than 15mm. It is important that both sides of the shield have the same height H. The Shielding Factor increases with the height of the shield H. Once the shield is high enough, approximately 15mm, a higher shield will not improve the Shielding Factor significantly. |

Influence of the Thickness t :

View | Influence |

| t has an influence on the saturation level of the shield. We recommend making t minimum 0.8mm. Once the shield is thick enough, the increase of the thickness will not improve the saturation level anymore. In the most of the case a shield thicker than 2mm is not needed. The saturation level increases with the thickness t of the shield. Once the shield is thick enough a increase of t will not improve the saturation level. |

What we can Offer:

Shields which are punched & bent or punched and deep drawn for various applications like electricity meters, electronic control protections in automobiles, avionics, medical devices, audio devices.

Magnetic Shields

Magnetic Shields

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!