|

Ningbo Joy Industrial & Trading Co.,Ltd.

|

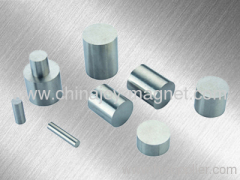

Custom Order Alnico magnets Permanent High performance

| Price: | 0.2~5.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Alnico magnets, composed of primarily aluminum, nickel, and cobalt, which is the most established and widely used magnet materials.

Introduction

Alnicos are precipitation-hardened alloys requiring special heat treatment techniques. The raw materials are Cobalt, Nickel, Copper, Aluminum and Iron. Titanium, silicon, etc. are added in certain proportions. The raw materials in their purest form are melted in medium frequency induction furnaces and castings are made using conventional sand or shell moulds. The heat treatment consists of heating the alloy in furnace to well above its curie point, and holding it at that temperature for some time. This is followed by controlled cooling after which the castings are reheated and held for a long period at a temperature of about 600 degrees. This ageing process increases the coercive force and the energy product. Finally, the castings are ground to obtain close dimensional tolerances whenever necessary and inspected for physical and magnetic accuracy.

Joy Magnet range of manufacturing includes all the below grades of AlNiCo. | |||||||||||||||||||||||||||||||||||||||||||||||||

We also have the expertise in manufacturing of isotropic magnets. These types of magnets have the unique property of exhibiting Multiple Poles. | |||||||||||||||||||||||||||||||||||||||||||||||||

Cast Alnico Materials - Physical and Mechanical Properties (Nominal values) | |||||||||||||||||||||||||||||||||||||||||||||||||

|

Cast Alnico Materials - Magnetic Properties (Nominal values) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Excellent temperature stability, high residual induction, and relatively high energies characterize AlNiCo material. They can be manufactured in number of complex shapes such as horseshoes.

Manufacturing Process

Applications and Dimensions

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Magnets Alnico

Alnico Permanent Magnet

Permanent Alnico Magnet

Bonded Alnico Magnets

Power Alnico Magnets

Alnico Bar Magnets

More>>