|

Ningbo Joy Industrial & Trading Co.,Ltd.

|

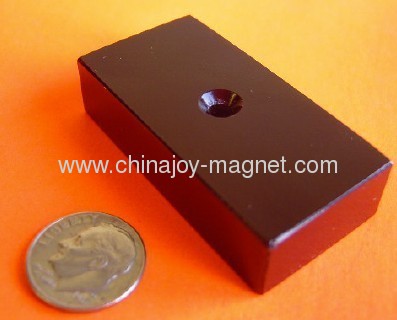

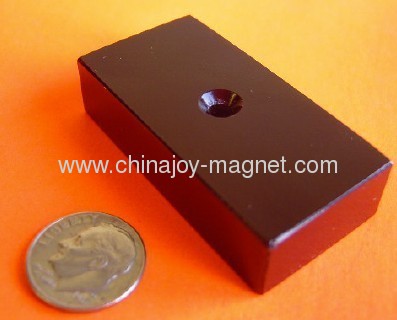

Dual Side Countersunk Hole Strong Neodymium Magnets Epoxy

| Price: | 9.0~11.0 USD |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Super strong neodymium rare earth N50 magnets

2" x 1" x 0.5" Thick Neodymium NdFeB Block Rare Earth Magnet with tapered countersunk hole

Product Description:

N50 Magnets

2" x 1" x 0.5" Thick Neodymium NdFeB Block Rare Earth Magnet with tapered countersunk hole

Extremely durable Epoxy + Copper + Nickel Triple Layer Coated with tapered center hole

Tapered counter sunk center hole on both sides of magnet to recess a screw head

Magnetized through the Thickness 0.5", poles are on the two 2x1" surfaces

NdFeB, the third generation of rare-earth permanent magnet, has high remanence, high coercive force, high-energy product and high performance/cost ratio.

2" x 1" x 0.5" Thick Neodymium NdFeB Block Rare Earth Magnet with tapered countersunk hole

Extremely durable Epoxy + Copper + Nickel Triple Layer Coated with tapered center hole

Tapered counter sunk center hole on both sides of magnet to recess a screw head

0.14" Diameter counter sunk center hole fits with #6 metal screws

Epoxy-Nickel-Copper-Nickel triple layer coated for maximum N52 magnets protection and durabilityEpoxy+Copper+Nickel 3-layer coating vs. Nickel+Copper+Nickel 3-layer coating

Epoxy + Copper + Nickel 3-layer coating has superior Corrosion Resistance and excellent adhesion to metal surface than Nickel + Copper + Nickel coating, this coating is ideal for bonding metal. Nickel+Copper+Nickel coating provides protection against moisture and oxygen but is prone to corrosion in salt and acidic conditions.

Magnetized through the Thickness 0.5", poles are on the two 2x1" surfaces

Neodymium rare earth magnets are the world's strongest magnets. All magnets are not created equal! Applied Magnets offers the highest quality magnets with consistent performance at lowest price. Our strong magnets are designed & manufactured to meet stringent quality standards using the latest technology.

neodymium magnets (also known as Neo, NdFeB, NIB or super magnets), a type of rare earth magnets, are the permanent magnet made from neodymium, iron, boron and other minor elements.

Super strong neodymium rare earth N50 magnets, stronger than N48, N45, N42, N40, N38 and N35

BrMax: 14500 gauss

neodymium magnets (also known as Neo, NdFeB, NIB or super magnets), a type of rare earth magnets, are the permanent magnet made from neodymium, iron, boron and other minor elements.

Super strong neodymium rare earth N50 magnets, stronger than N48, N45, N42, N40, N38 and N35

BrMax: 14500 gauss

Approximate pull force: 89 lbs

ISO certified strong neodymium rare earth magnets with the best corrosion-resistant coating of Epoxy + Copper + Nickel.

NdFeB, the third generation of rare-earth permanent magnet, has high remanence, high coercive force, high-energy product and high performance/cost ratio.

Neodymium Magnets are easily formed into various sizes and widely used in many fields such as magnets for aviation, electronics, instruments, meters, machine and medical instruments. Neodymium metal is used extensively to produce Nd-Fe-B magnets, which have energy densities as high as 27 to 35 million gauss oersteds.

They are the most compact magnets commercially available. It is especially suitable for the development of magnets for high-performance, compact and light products.

Specification:

1. Meterial: Neodymium, NdFeB

2. Magnetic properties:High coercive force, the max operation temp is up to 200 degree centigrade or 380 curie temperature;

3. Grades: N33-N52, 33M-48M, 33H-48H, 30SH-45SH, 30UH-38UH and 30EH-35EH;

4. Shapes and sizes:Various kinds or according to customers' request .

5. Coatings: Ni, Zn, Phosphating, epoxy and so on;

6. Motor magnet Applications:Widely used in different applications, such as sensors, motors, rotors, wind turbines/wind generators, loudspeakers, magnetic hooks, magnetic holder, filters automobiles and so on.

6. Motor magnet Applications:Widely used in different applications, such as sensors, motors, rotors, wind turbines/wind generators, loudspeakers, magnetic hooks, magnetic holder, filters automobiles and so on.

7. Quality Control : Our QC team consistsof more than 12 professional people to ensure 100% products high quality .

8. Extremer Power Warming : These magnets are dangerous !If your fingers are trapped between two they will cut your skin. Please be note they shouldonly be handled with great care .

9. Transportation :All available shipping ways could be applied ,by courier ,by air or by sea . Appinted shipping company or our own forwarders all could be used in shipment .Full-way tracking the cargos for you before th good arrival .

Our factory can also manufacture various sizes of other NdFeB magnets, according to the customer's specification

Magnetic properties of main grades

| Grade | Residual Induction | Coercive Force | Intrinsic Coercivity | Maximum Energy Product | TW | ||||

| Br | BHC | IHC | (BH)max. | ||||||

| kGs | T | kOe | kA/m | kOe | kA/m | MGOe | kJ/m3 | ℃ | |

| N33 | 11.3-11.7 | 1.13-1.17 | ≥10.5 | ≥836 | ≥12 | ≥955 | 31-33 | 247-263 | 80 |

| N35 | 11.7-12.1 | 1.17-1.21 | ≥10.9 | ≥868 | ≥12 | ≥955 | 33-36 | 263-287 | 80 |

| N38 | 12.1-12.5 | 1.21-1.25 | ≥11.3 | ≥899 | ≥12 | ≥955 | 36-39 | 287-310 | 80 |

| N40 | 12.5-12.8 | 1.25-1.28 | ≥11.6 | ≥923 | ≥12 | ≥955 | 38-41 | 302-326 | 80 |

| N42 | 12.8-13.2 | 1.28-1.32 | ≥11.6 | ≥923 | ≥12 | ≥955 | 40-43 | 318-342 | 80 |

| N45 | 13.2-13.8 | 1.32-1.38 | ≥11.0 | ≥876 | ≥12 | ≥955 | 43-46 | 342-366 | 80 |

| N48 | 13.8-14.2 | 1.38-1.42 | ≥10.5 | ≥835 | ≥11 | ≥876 | 46-49 | 366-390 | 80 |

| 33H | 11.3-11.7 | 1.13-1.17 | ≥10.5 | ≥836 | ≥17 | ≥1353 | 31-34 | 247-271 | 120 |

| 35H | 11.7-12.1 | 1.17-1.21 | ≥10.9 | ≥868 | ≥17 | ≥1353 | 33-36 | 263-287 | 120 |

| 38H | 12.1-12.5 | 1.21-1.25 | ≥11.3 | ≥899 | ≥17 | ≥1353 | 36-39 | 287-310 | 120 |

| 40H | 12.4-12.8 | 1.24-1.28 | ≥11.6 | ≥923 | ≥17 | ≥1353 | 38-41 | 302-326 | 120 |

| 42H | 12.8-13.2 | 1.28-1.32 | ≥12.0 | ≥955 | ≥17 | ≥1353 | 40-43 | 318-342 | 120 |

| 33SH | 11.3-11.7 | 1.13-1.17 | ≥10.6 | ≥844 | ≥20 | ≥1592 | 31-34 | 247-272 | 150 |

| 35SH | 11.7-12.1 | 1.17-1.21 | ≥11.0 | ≥876 | ≥20 | ≥1592 | 33-36 | 263-287 | 150 |

| 38SH | 12.1-12.5 | 1.21-1.25 | ≥11.4 | ≥907 | ≥20 | ≥1592 | 36-39 | 287-310 | 150 |

| 40SH | 12.4-12.8 | 1.24-1.28 | ≥11.8 | ≥939 | ≥20 | ≥1592 | 38-41 | 302-326 | 150 |

| 28UH | 10.2-10.8 | 1.02-1.08 | ≥9.6 | ≥764 | ≥25 | ≥1990 | 26-29 | 207-231 | 180 |

| 30UH | 10.8-11.3 | 1.08-1.13 | ≥10.2 | ≥812 | ≥25 | ≥1990 | 28-31 | 223-247 | 180 |

| 33UH | 11.3-11.7 | 1.13-1.17 | ≥10.7 | ≥852 | ≥25 | ≥1990 | 31-34 | 247-271 | 180 |

| 28EH | 10.4-10.9 | 1.04-1.09 | ≥9.8 | ≥780 | ≥30 | ≥2388 | 26-29 | 207-231 | 200 |

| 30EH | 10.8-11.3 | 1.08-1.13 | ≥10.2 | ≥812 | ≥30 | ≥2388 | 28-31 | 223-247 | 200 |

neodymium magnet

1.Material:rare earth ,neodymium -Iron-Boron

2.Shape:Tile,Ring,Disc,Block,Cylinder,Tile,Arc,customers

2.Shape:Tile,Ring,Disc,Block,Cylinder,Tile,Arc,customers

3.Size:4X3mm,5X3mm,8X3mm,30X5mm,15X7mm or customized

4.Grade:N35-N52,N30M-N48M,N35SH-N45SH,etc.

4.Grade:N35-N52,N30M-N48M,N35SH-N45SH,etc.

5.Coating :NiCuNi, Ni,Zn,Gold,Silver,Epoxy,chemical plating Ni,etc.

6.Application: Sensors, Motors, Rotors, Wind turbines/wind generators, Loudspeakers, Magnetic hooks & holder, Filters, Automobiles, Jewelry.etc.

Neodymium magnet advantages

a) High energy

b) Very high Hc and Hci output

c) More economical than SmCo

d) Wonderful performance at ambient temperature

a) High energy

b) Very high Hc and Hci output

c) More economical than SmCo

d) Wonderful performance at ambient temperature

Transportation

All available shipping ways could be applied, by courier, by air or by sea.

Appointed shipping company or our own forwarders all could be used in shipment.

Full-way tracking the cargos for you before the goods arrive.

Buyer Guide

In order to quote you the best price quickly, please provide the following information:

1.Product size,grade,coating,etc.

2.Order quantity;

3.Attached the drawings if customized

4.Any special packing or other requirements

4.Any special packing or other requirements

Our advantage

1. Fast reply: all your enquiry will be replied within 24 hours;

2. Reasonable price: we are direct manufacturer and able to offer better price;

3. Good quality: we are experienced in quality control;

4. Fast delivery time:7-20 days.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Magnets Neodymium

Epoxy Magnets

Strong Block Magnets

Cylinder Neodymium Magnets

Disc Neodymium Magnets

Neodymium Disc Magnets

More>>