|

Ningbo Joy Industrial & Trading Co.,Ltd.

|

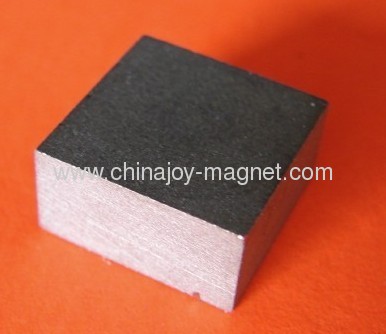

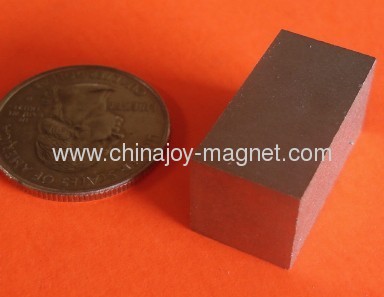

Strong Magnet Block SmCo magnet

| Price: | 0.2~5.0 USD |

| Payment Terms: | T/T,L/C, |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Constitution:35%Sm,60% Co and 5%Fe&Cu.

2.SmCo magnet has superior resistance to high temperature (max temperature reaches 350 degree cetigrade ).

Features of Block SmCo magnet

1.Constitution:35%Sm,60% Co and 5%Fe&Cu.

2.SmCo magnet has superior resistance to high temperature (max temperature reaches 350 degree cetigrade ).

When working at above 180 degree cetigrade,its maximum energy product Bh and temperature stability sre much better than NdFeb magnet.

3.No coating is needed for the surface protecting,Because of excellent resistance.

4.SmCo is very suitable for machines with high magnetic requirements and good for strict working environment requirements.

Application:

Electronic Magnetron

Magnetic Transmission

Magnetic Treatment

Magnistor

Other Application

Block SMCO Magnets with High Property

PLEASE tell us yourdimension as follows:

Shape: Cylinder, Ring, Square etcs.

Size: OR*IR*LENGTH*ANGEL( arc shape)

OR*IR*THICKENESS (for ring shape)

Drawings would be highly appreciated

Grade: S16,S18,S20,S180,S22A,S22B,S240,S26A,S26B,S280,S270,S300

Magnetized direction: through thickness/length/ diameter/ axial/ isotropic/anisotropic, and pair magnetized

Tolerance:unless specified requirements, +/-0.1mm,+/-0.05mm

Block SMCO Magnets with High Property

Block SMCO Magnets with High Property

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Smco Magnet Block

SmCo Magnet

Strong Magnet

Smco Permanent Magnet

Smco Rare Earth Magnet

Sintered Smco Magnet

More>>